In the context of composite requirements for material performance in the era of Industry 4.0, our cold-rolled

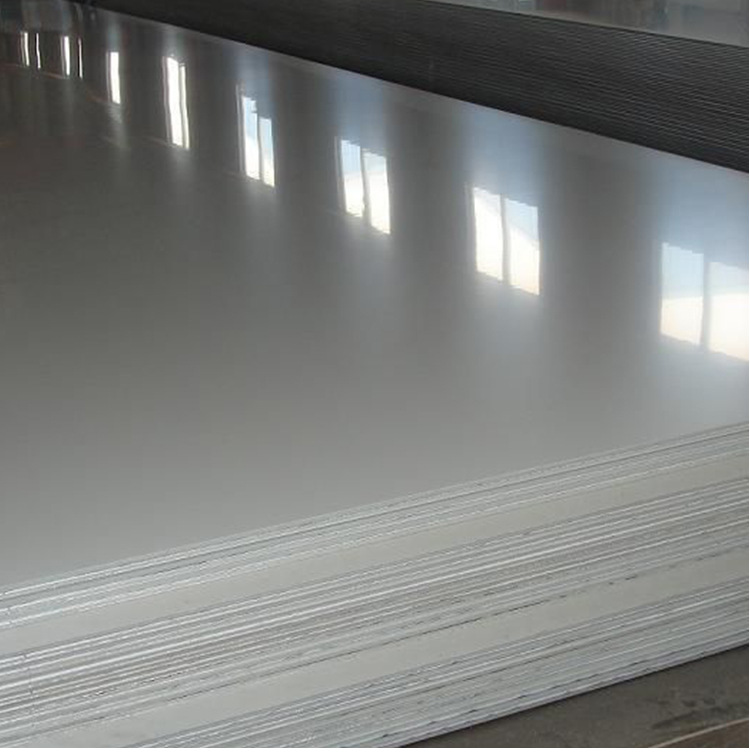

Carbon Steel Coils have redefined product value systems with multi-dimensional adaptability. Based on a million-level operational database, our material selection model precisely matches performance parameters for different industries: optimizing edge thinning rate to ≤8% for container manufacturing needs, meeting continuous roll forming processes; developing special zinc-based composite coatings for architectural curtain walls, achieving salt spray test durations exceeding 720 hours; introducing ultra-deep drawing grade steels (r value ≥ 2.1) for new energy battery casings, increasing stamping qualification rates to 99.6%. Our products have passed 12 international certifications including ISO 9001 and IATF 16949, with grain sizes controlled within the range of 9-10 grades.

Our manufacturing system fully integrates green intelligent manufacturing concepts, utilizing photovoltaic power generation and acid regeneration technologies, reducing carbon footprints by 37% compared to traditional processes. Leveraging an intelligent warehousing system, we achieve nationwide delivery network coverage within 72 hours, supporting flexible supply models of small batches and multiple shipments. Our proprietary lifecycle cost assessment tool helps customers quantify overall benefits from raw material procurement to waste recycling, ensuring core indicators such as tensile strength (420-550 MPa) and hardness (65-85 HRB) lead the industry while reducing comprehensive usage costs by approximately 15% through process integration optimization, truly achieving a deep coupling of high performance and economic efficiency.

In the context of composite requirements for material performance in the era of Industry 4.0, our cold-rolled Carbon Steel Coils have redefined product value systems with multi-dimensional adaptability. Based on a million-level operational database, our material selection model precisely matches performance parameters for different industries: optimizing edge thinning rate to ≤8% for container manufacturing needs, meeting continuous roll forming processes; developing special zinc-based composite coatings for architectural curtain walls, achieving salt spray test durations exceeding 7...

In the context of composite requirements for material performance in the era of Industry 4.0, our cold-rolled Carbon Steel Coils have redefined product value systems with multi-dimensional adaptability. Based on a million-level operational database, our material selection model precisely matches performance parameters for different industries: optimizing edge thinning rate to ≤8% for container manufacturing needs, meeting continuous roll forming processes; developing special zinc-based composite coatings for architectural curtain walls, achieving salt spray test durations exceeding 7...