4189162416

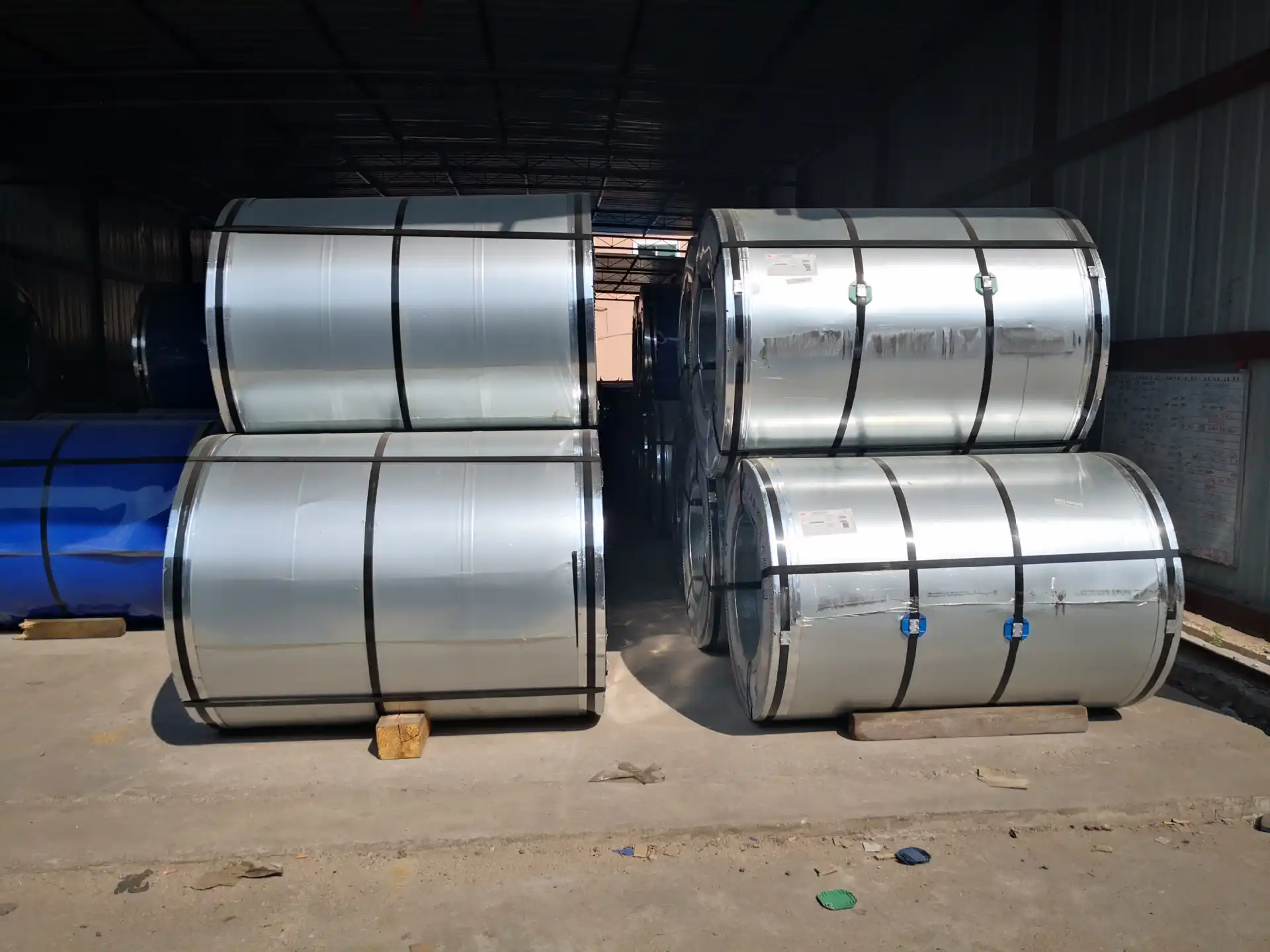

Product Number: 4189162416

HITS: 396 DATE: 2025/4/18

SPECS: complete in specifications

PRICE: Bargaining

UNIT: TON/MT

PLACE: China

Description

The galvanized coil is used to immerse the thin steel plate in the melted zinc tank to make a layer of zinc thin steel plate adhere to its surface. It is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in a plating tank with zinc dissolved into a galvanized steel plate; alloyed galvanized steel plate. This steel plate is also made by hot dip method, but after being discharged from the tank, it is immediately heated to about 500°C to form an alloy film of zinc and iron. This galvanized coil has good coating bonding and welding properties. (1) Normal zinc flower coating. During the normal solidification process, zinc grains grow freely to form a coating with obvious zinc flower morphology. (2) Minimized spangle coating During the solidification process of the zinc layer, the zinc grains are artificially restricted to form the smallest zinc coating as possible. (3) Spangle-free plating layer obtained by adjusting the chemical composition of the plating solution, the plating layer does not have a visual morphology of zinc flowers and a uniform surface. (4) Zinc-iron alloy coating The steel strip after passing through the galvanizing tank solution is heat treated to make the entire plating layer form a zinc and iron alloy layer. This plating layer has a dark gray appearance, no metallic luster, and is easy to powder during the vigorous forming process. It is suitable for coating directly without further treatment except for general cleaning. (5) Differential coating Differential coating For both sides of the galvanized steel plate, a coating with different zinc layer weights is required. (6) Skin pass Skin pass Skin is a cold rolling processing of tiny deformation of galvanized steel plates for one or several purposes. Improve the appearance of the surface of galvanized steel plates or suitable for decorative coatings; temporarily minimize the phenomenon of slip lines (Rudes lines) or folded marks when the finished product is not processed.